Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

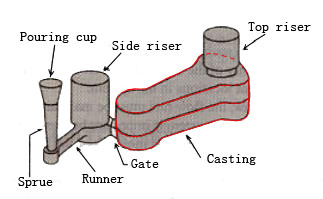

Casting is one of the basic processes of modern machinery manufacturing industry.

Casting is a production process in which metal is smelted into a liquid that meets certain requirements, poured into a mold, cooled, solidified, and cleaned to obtain a predetermined shape, size or performance. Since the casting blank is almost formed, the purpose of free machining or a small amount of processing is achieved, thereby reducing the processing cost and shortening the production cycle to a certain extent.

There are many types of casting, which are divided into:

1. Ordinary sand casting, including three types of wet sand, dry sand and chemically hardened sand.

2. Special casting can be divided into the following two types according to the molding material:

①. Special casting with natural mineral sand and gravel as the main modeling material (such as investment casting, mud casting, shell casting in foundry workshop, negative pressure casting, solid casting, ceramic casting, etc.)

②. There are two types of special casting with metal as the main casting material (such as metal mold casting, pressure casting, continuous casting, low pressure casting, centrifugal casting, etc.).

Casting is a relatively economical blank forming method, and it is more economical for parts with complex shapes. Such as the cylinder block and cylinder head of the car engine, the propeller of the ship, and the exquisite works of art. Some difficult-to-cut parts, such as nickel-based alloy parts for gas turbines, cannot be formed without casting.

In addition, the size and weight of cast parts can be adapted to a wide range, and the types of metals are almost unlimited; while the parts have general mechanical properties, they also have comprehensive properties such as wear resistance, corrosion resistance, shock absorption, etc., which are suitable for other metal forming methods such as forging , rolling, welding, punching, etc. can not do. Therefore, the rough parts produced by the casting method in the machine building industry are still the largest in quantity and tonnage.

Please contact us if you have any casting or machining needs.

November 18, 2024

November 11, 2024

E-posta denna leverantör

November 18, 2024

November 11, 2024

October 24, 2022

June 13, 2022

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.